Electrolyzers: Integral Tools Driving Progress in Electrochemical Science and Industry

The Evolution of Electrolyzers

Historically, electrolyzers were primarily associated with water splitting—a process used to produce hydrogen and oxygen through electrochemical reactions. This early application played a critical role in advancing our understanding of electrochemical systems and paved the way for innovations in sustainable energy solutions.

What are Electrolyzers Today?

Modern electrolyzers have evolved far beyond their initial role in water splitting. They now provide a versatile framework where electrical current drives complex electrochemical reactions at the integrated interfaces of gas-liquid-solid phases. These interfaces facilitate interactions among reactants, intermediates, and products, enabling groundbreaking advancements in various fields of science and technology. As a result, electrolyzers have become an essential tool in sectors including green energy, energy transport and storage, sustainability, chemical manufacturing, and renewable fuels.

Applications of Electrolyzers

- CO2 Reduction Reactions (CO2RR and CORR): Electrolyzers play a pivotal role in converting carbon dioxide into valuable chemicals and fuels, aiding carbon capture and utilization efforts. By leveraging advanced catalyst designs, they enhance the efficiency and selectivity of these reactions.

- Water Electrolysis (OER and HER): Electrolyzers drive the oxygen evolution reaction (OER) and hydrogen evolution reaction (HER) processes in Proton Exchange Membrane Water Electrolysis (PEMWE) and Anion Exchange Membrane Water Electrolysis (AEMWE). These technologies are essential for producing green hydrogen for energy and industrial applications.

- Flow Batteries: Electrolyzers support both organic and inorganic flow battery systems, enhancing their storage capacity and efficiency for renewable energy systems.

- Fuel Cells: Facilitating the production of high-purity hydrogen, electrolyzers contribute to the development and operation of efficient fuel cell technologies for clean energy generation.

- Carbon Capture: Electrolyzers enable advanced carbon capture technologies by integrating electrochemical processes that transform captured carbon into reusable or valuable materials.

- Waste Removal and Polymer Breakdown: Electrolyzers are being increasingly utilized in research and applications related to waste removal, including the degradation of pollutants and toxic materials. They also play a critical role in breaking down complex polymers into simpler, reusable components, advancing sustainable material management and recycling technologies.

- Chemical Synthesis: Driving a variety of electrochemical reactions, electrolyzers aid in the production of valuable intermediates and final products for industrial and research applications.

Challenges in Electrolyzer Development

Despite their transformative potential, electrolyzers face several challenges:

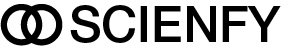

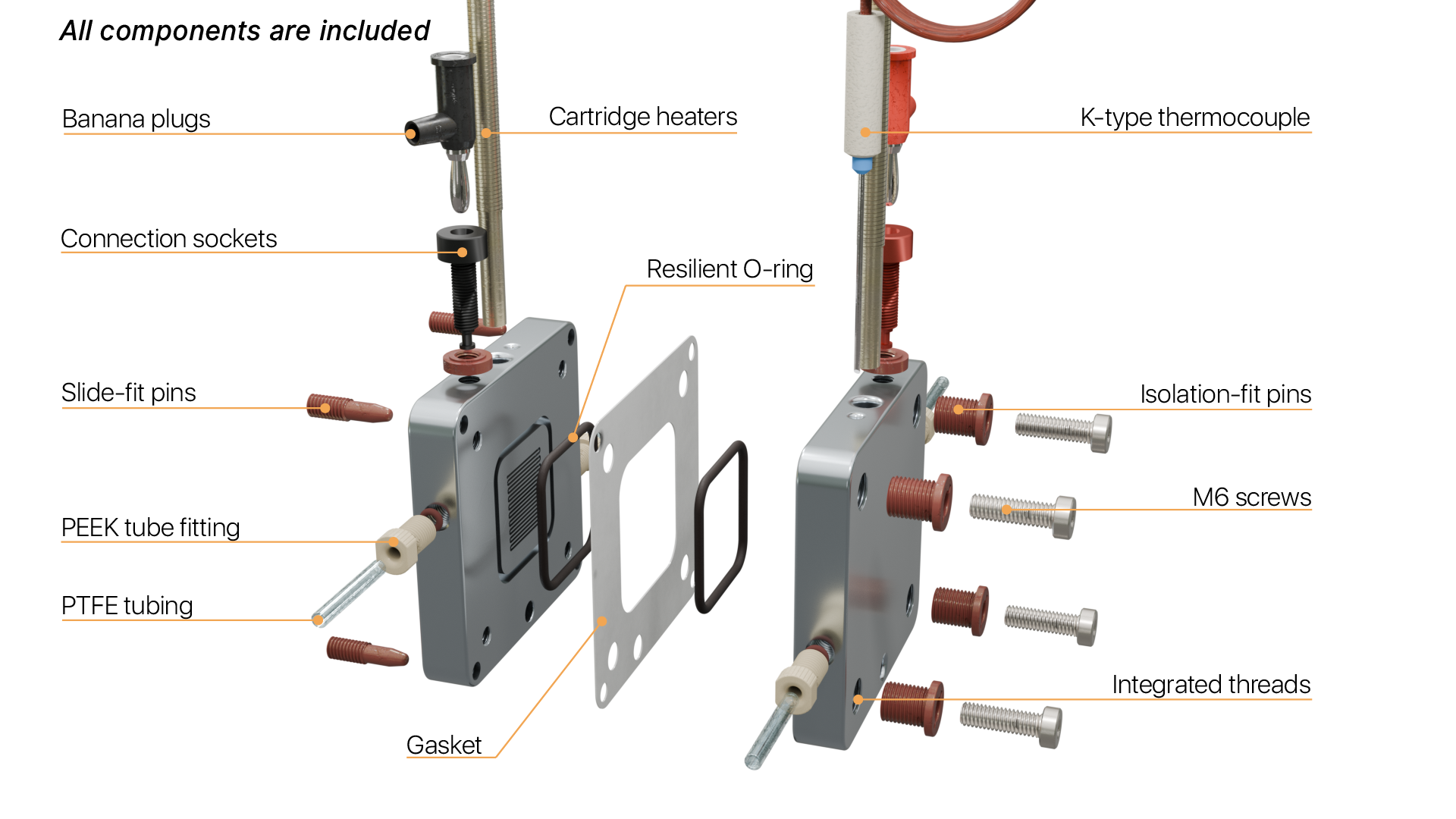

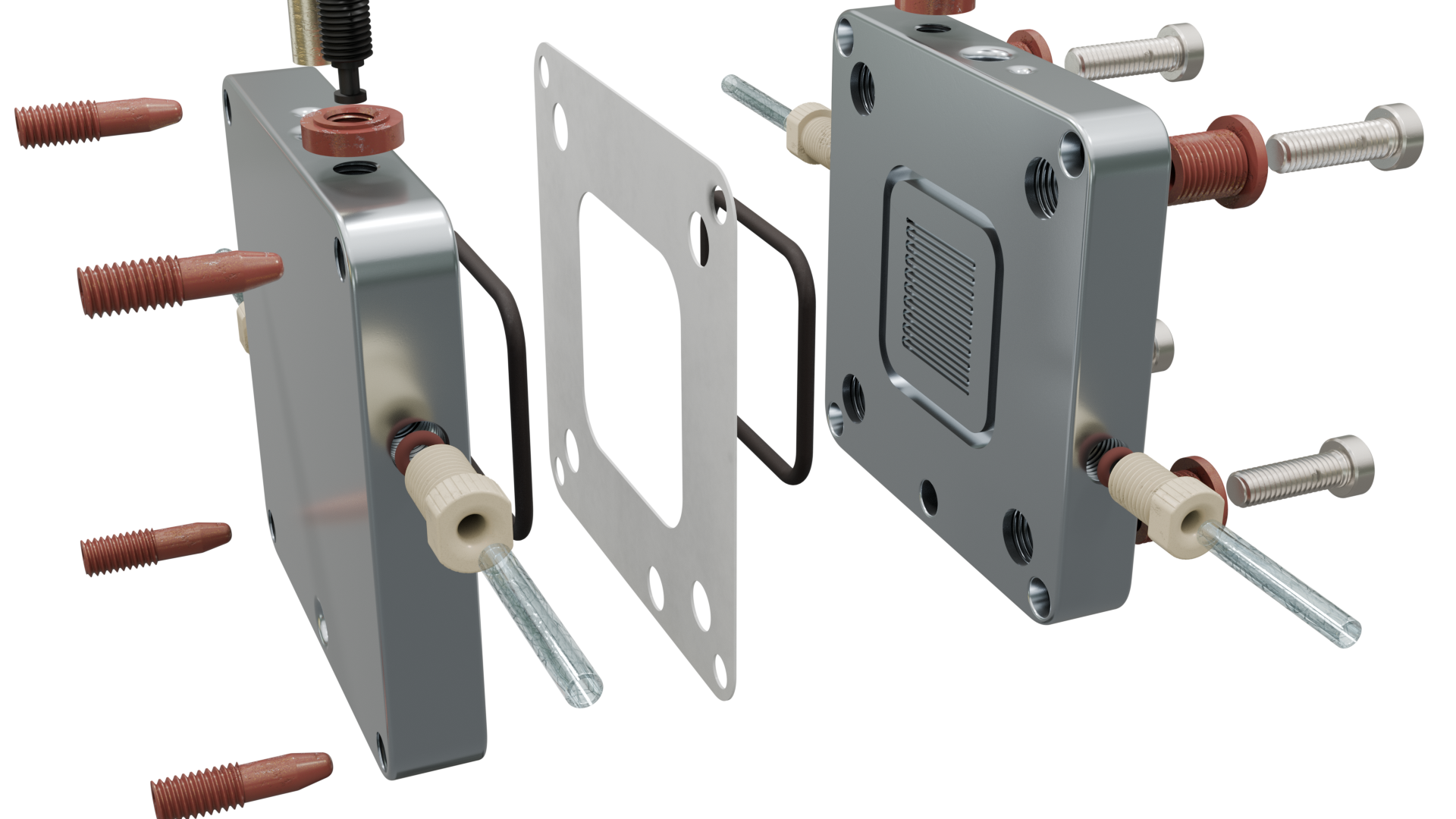

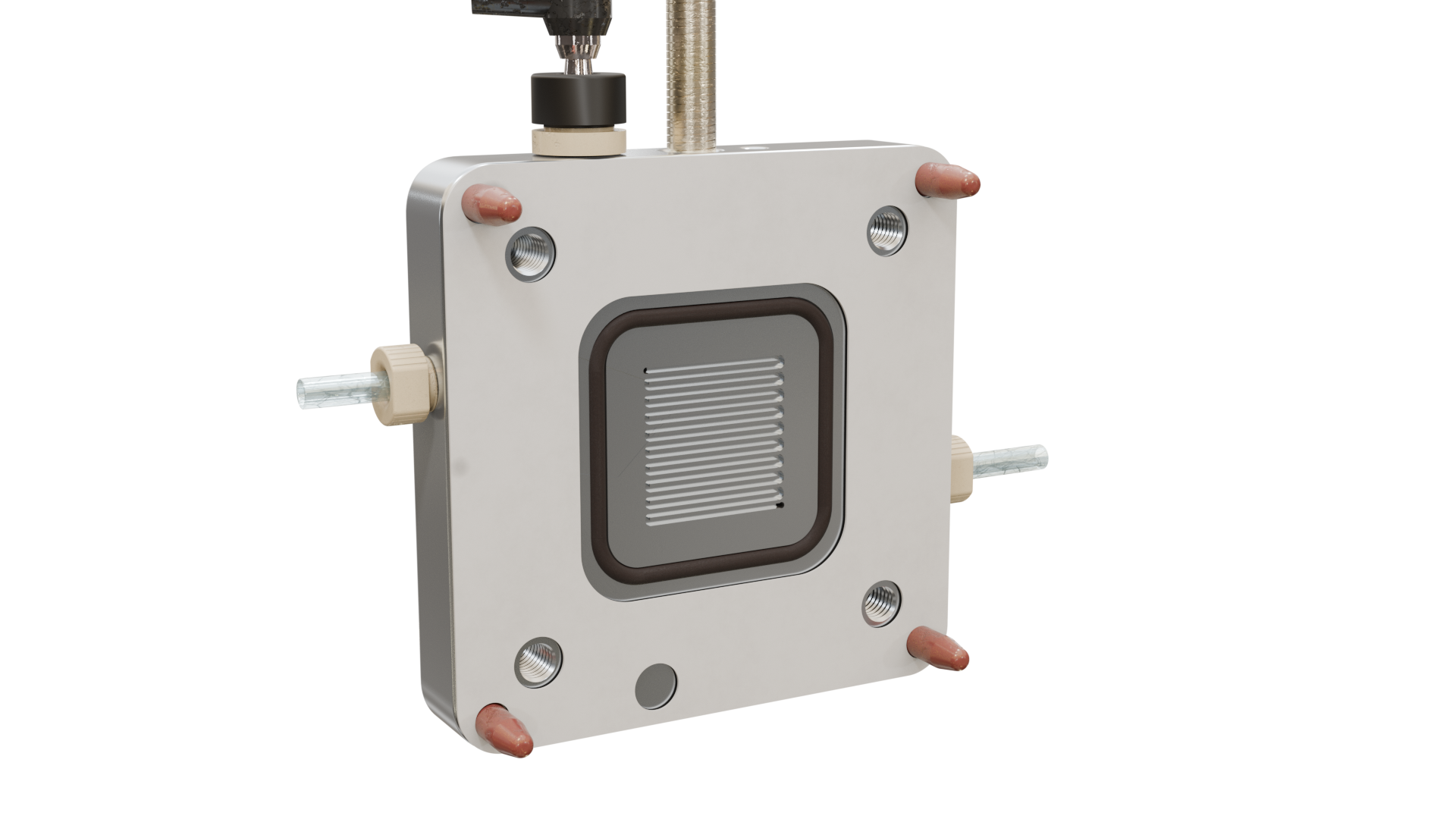

- Reproducible Assembly: A significant challenge in electrolyzer use is the assembly of the cell stack. This process is often time-consuming and prone to variability, such as inconsistencies in compression forces and misalignment of components. These issues can lead to unreliable performance and difficulty in reproducing results. At the core of solving this challenge is thoughtful design. Electrolyzers must be engineered to simplify assembly processes, reduce variability, and ensure consistent operation under controlled conditions.

- Standardization Across Laboratories: The lack of universally accepted standards in electrolyzer setups often leads to disparities in reported outcomes. Establishing standardized protocols and benchmarks is essential for improving cross-lab comparability and accelerating scientific progress.

- High-Quality Manufacturing: Precision manufacturing techniques are critical for translating robust designs into dependable systems. High-quality fabrication ensures that every electrolyzer meets the intended specifications and delivers reliable performance.

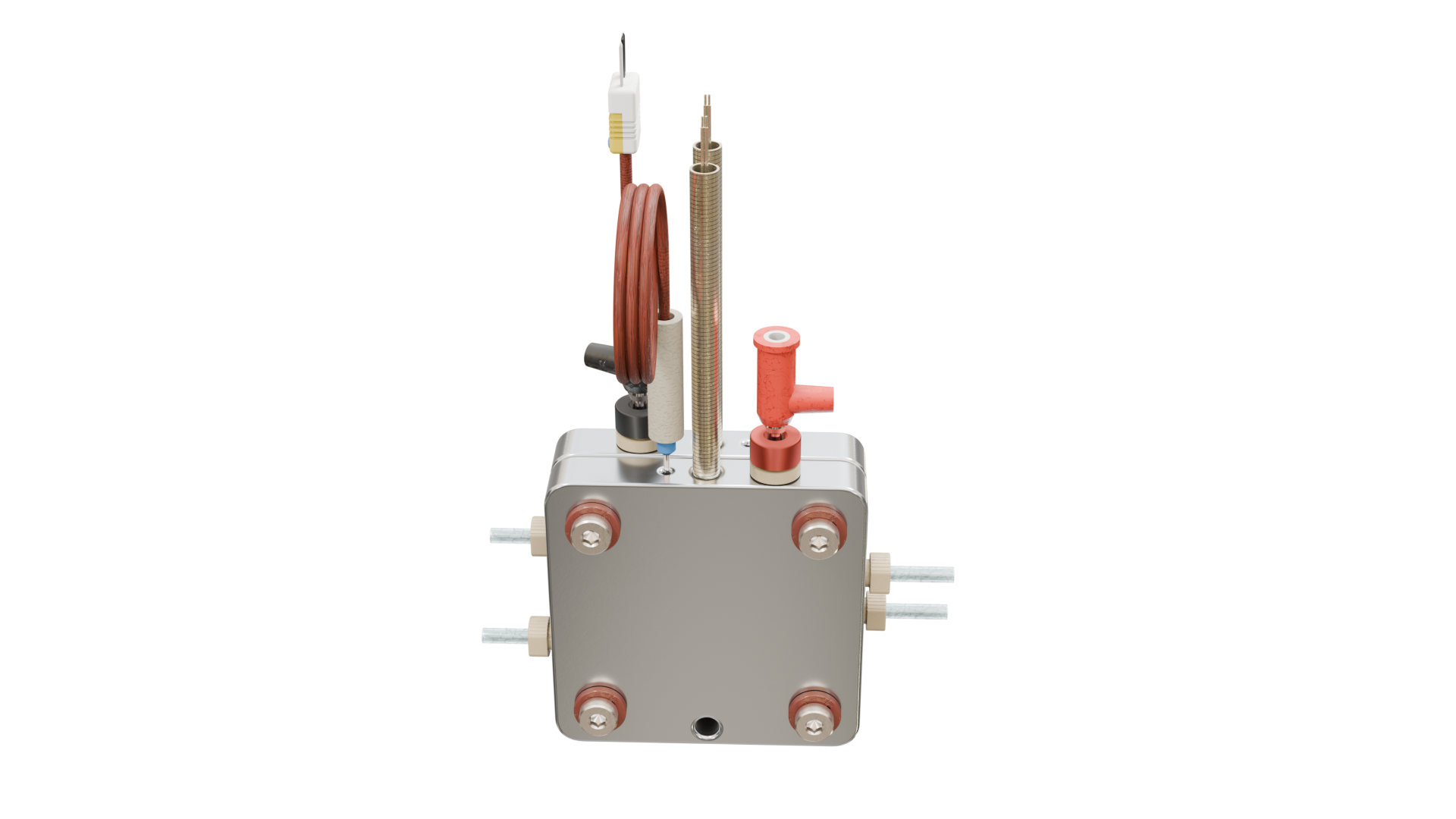

- Fine Control Over Parameters: Achieving precise control of key parameters, such as temperature, pressure, current density, and catalyst composition, is essential for optimizing performance and enabling high-throughput data collection.

- Material Durability: Developing materials that can withstand the harsh conditions of electrochemical reactions over prolonged periods remains a critical challenge.

- Efficiency and Scalability: Enhancing energy efficiency and scaling up electrolyzer designs to meet industrial demands require continued innovation and resource investment.

- Integration with Renewable Energy Sources: Synchronizing electrolyzers with intermittent renewable energy sources, such as solar and wind, necessitates advanced system designs and smart energy management strategies.

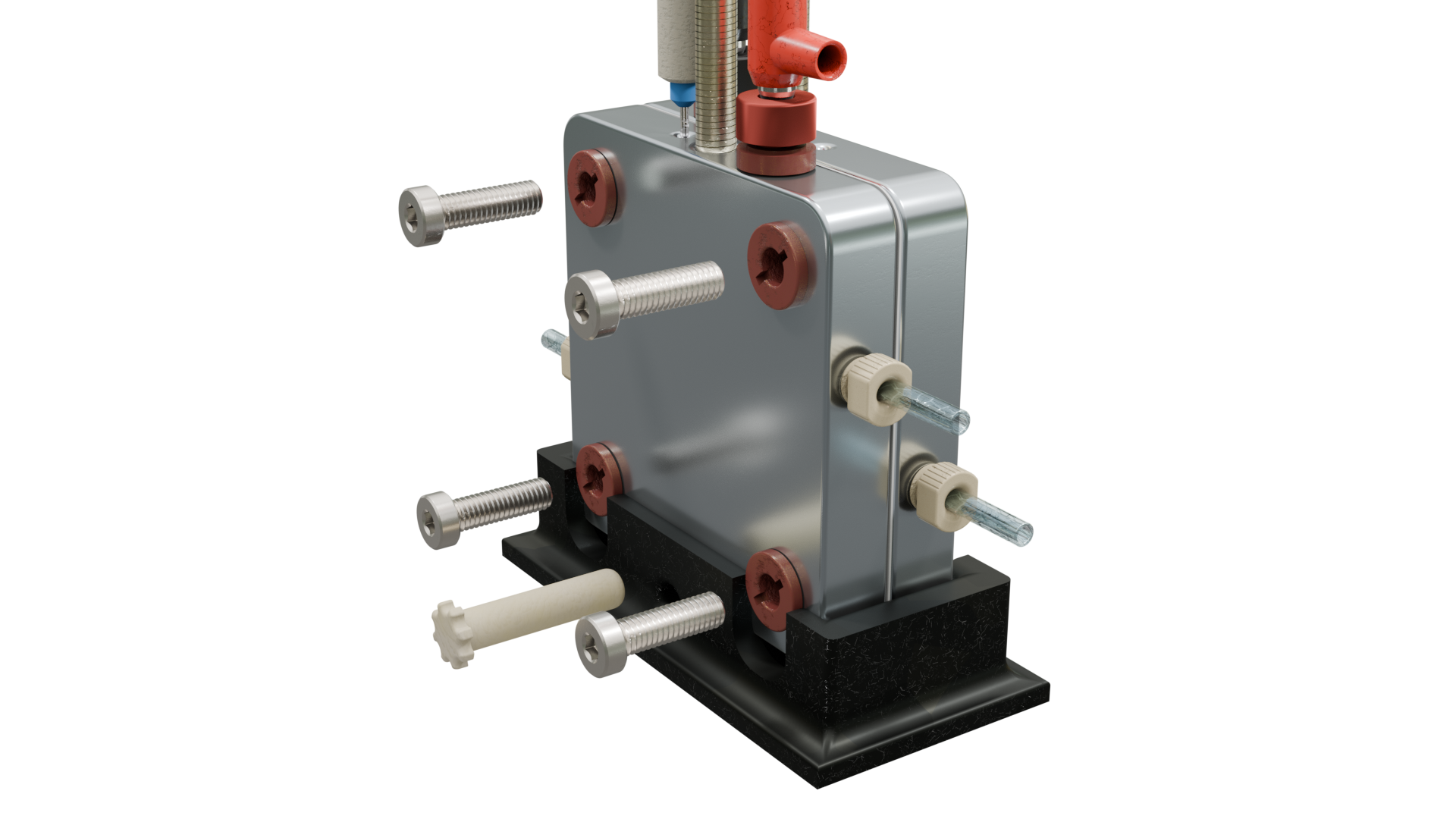

SCIENFY Electrolyzers: Robust by Design

At Scienfy, we meticulously iterate through design, testing, and development to address the key challenges in electrolyzer technology. Our approach focuses on robustness, ease of assembly, and reproducibility. By designing systems that simplify the assembly process and minimize variability, we provide reliable, high-performing electrolyzers tailored to your needs.

Explore our generations of electrolyzers, each crafted for specific functionalities and complexities. Whether for fundamental research or industrial applications, Scienfy electrolyzers represent a commitment to precision, innovation, and quality.

EleXer One

Advanced electrolyzer